Let's shape the unseen future.

Using machine vision to improve quality assurance.

OVERVIEW

Glaston is a leading manufacturer of tempered glass.

The quality of glass is controlled by a glass fragmentation test which is carried out manually by humans several times a day, taking up to an hour of their workday.

The Challenge

How can we reduce time spent on critical quality assurance testing of tempered glass without compromising results?

In collaboration with design agency, Nordkapp, we were challenged with finding ways to use technology to automate this task and reduce the labor time.

Our deep knowledge and understanding of Machine Vision technologies meant we were a natural technology partner for Nordkapp to build a technology solution that would not only do what was required, but live up to the desired brand experience.

Video courtesy of Nordkapp

Our Solution

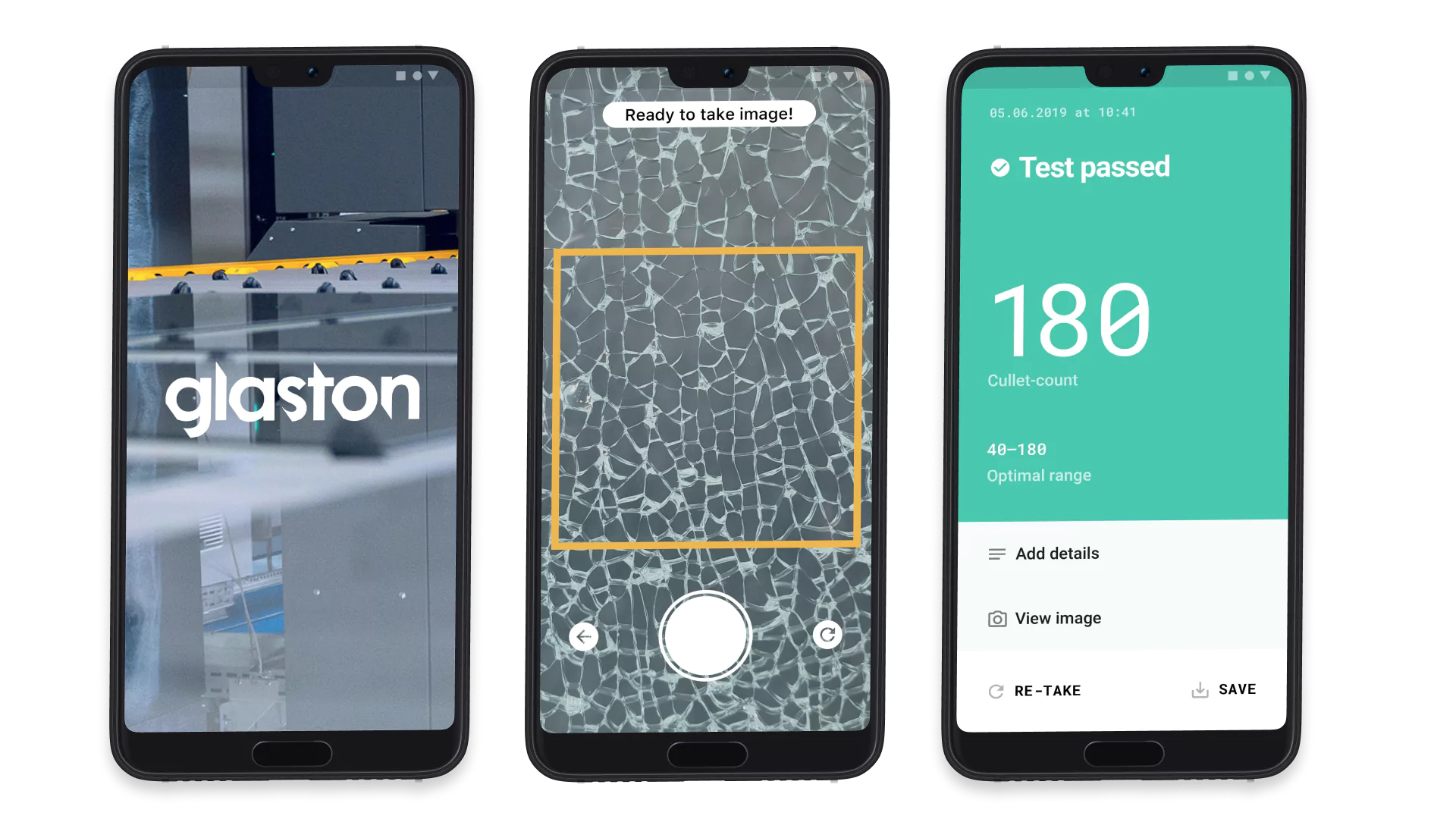

Leveraging machine vision, we built a 2 part system.

The first technology solution would isolate the relevant area within the glass sheet to measure from eliminating the need for manually isolating the 1 inch square area required for calculating the cullet count by using crude templates. With the area defined the next challenge was to isolate and count the distinct facets of glass within that area. Again, using machine vision technologies to enhance the facets and break lines it was then far easier to isolate complete facets and count the number of them within the area defined.

Improved Accuracy

In order to determine the cullet-count of tempered glass, it must be shattered and an average value determined for the number of individual facets of glass created in the process. What was a manual process, could now be taken on utilizing Machine vision technology to analyze images of the shattered glass an determine the count automatically.

Precision in your pocket

The workforce within Glaston is constantly on the move from one area to another, as well as out in the field. By packaging up the technology solution into an app that can run on anyone's smartphone, the benefit of the Siru technology goes everywhere the user does.

Time Saving Automation

Because the machine vision solution can calculate the cullet count in a fraction of the time, the savings per employee for Glaston from time saved was huge. from up to an hour a day to minutes. Historical records as well as automatic digital reports from tests also helped improve efficiency even more.

Results

The Glaston Siru App is now in regular use and a standard application on employees smartphones.

The cumulative impact of time saving has resulted in the ability to output more product confidently and improved the daily tasks of the employees allowing them to focus their time on other important areas of the production process.

Time saved on individual task of conducting a test

Increased volume of complete tests undertaken per day

Markku Pulkinnen

CTO, Younite

This project was a great example of the power of Machine Vision. What used to be a time-consuming manual process is now a more reliable machine vision solution that works in a matter of seconds and is more precise than a human could ever be.

Related...

YOUNITE • INDUSTRIAL AI

INSIGHTS

New York

860 Broadway

6th Floor

New York, NY 10003

Helsinki

Aleksanterinkatu 17

00100

Helsinki, Finland

Oulu

Kirkkokatu 13

90100

Oulu, Finland

Follow

© 2025 Younite AI Oy

Younite AI is registered in the European Union, the USA, Japan, and various other jurisdictions. Privacy Statement.